Description

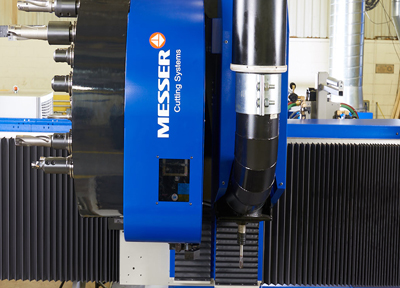

An optional drill feature can be combined with plasma and oxyfuel cutting, allowing for more work to be done on the piece part in a single handling. All processes are done in the same set-up, providing accurate, feature-to-feature relationships, both within a single piece and from part to part.

The four inch drill unit can be activated using a CNC command in the part program or by the operator. After activation, the hold down clamps push down on the plate prior to and during the entire drilling cycle. The tool cutting speed, feed per revolution, and length are maintained in the database.

- Drilling up to 2.5″ diameter on 6″ thick mild steel.

- Tapping up to 1 ½”.

- Optional chip recovery system.

- X-Y milling capability.

- 49.8 HP peak (24.3 HP continuous), 2-1/2″ capacity drill.

- Constant torque, AC liquid cooled servo motor.

- The 23.5″ drill stroke is feed-rate controlled to provide reliable drilling.

- CAT 50 taper spindle.

- 24 tool capacity.